Introduction

This seminar takes an in-depth look at the divisive field of data communications and Fieldbus systems. The increasing trend towards digital communications within the industrial plant environment has brought in its wake a myriad of problems concerned with interconnectivity and differing standards offered by a wide variety of competing vendors. For the user, it has become progressively more difficult to differentiate between the proffered options.

Training Methodology

Designed for both novice and experienced engineers and technicians, this seminar starts at fundamental principles and progresses through basic coding and formatting systems, error detection, and protocols through to advanced Fieldbus and device networking concepts.

Throughout the course, participants will learn through active participation using exercises, questionnaires, and practical troubleshooting using protocol analysis and covering:

- RS 232

- RS 485

- Modbus

- Networking

- TCP/IP

Organizational Impact

Following the training and development experience provided by this workshop, participants will return to their organizations equipped with new skills and knowledge that will enable them to evaluate the impact of new and existing technology in respect of your plant's communication strategy and apply a rationalized communication philosophy based on the best available practices.

By leveraging these skills, your enterprise can expect an improvement in overall productivity through the reduction in downtimes resultant from inappropriate data communications strategy and through the ability to apply, install, and troubleshoot a modern digital communication system.

Personal Impact

On successful completion of this course, delegates will be able to:

- Appreciate the basic principles of data communications

- Understand the essential differences between asynchronous and synchronous transmission

- Apply basic faultfinding techniques covering rs232 up to rs485

- Understand the importance of the iso osi model

- Understand the basis of cyclic redundancy

- Recognise the different aspects of cable selection

- Apply different shielding technologies

- Understand the application of fibre optics

- Appreciate the value of hart in both calibration, data collection and diagnostics

- Recognise the wide range of fieldbus options

- Apply modbus in a practical manner and make use of troubleshooting techniques

- Differentiate between modbus and modbus plus

- Gain an insight into the essential differences between asibus and devicenet

- Make an informed appraisal of the differences between profibus and foundation fieldbus

- Understand the basics of ethernet

- Appreciate the application of ethernet in the industrial environment

- Understand tcp/ip and its associated protocols

- Differentiate between net and sub-net masking

- Distinguish the functionality of ports and sockets

Who Should Attend?

- Professionals involved in designing, selecting, sizing, specifying, installing, testing, operating and maintaining data communication and Fieldbus systems

- Any professional needing to get to grips with the ever expanding and complex field of data communications and Fieldbus systems

- Automation Engineers

- Chemical Engineers

- Consulting Engineers

- Electrical Engineers

- Electricians

- Industrial IT specialists

- Installation and maintenance technicians

- Instrumentation and Control Engineers

- Maintenance Engineers

- Operations Engineers

- Process Engineers

- Process Operators

- Production professionals

- Project professionals

- System Integrators

- Other professionals who want a better understanding of the subject matter

SEMINAR OUTLINE

DAY 1

Introduction to Data Communications

- Overview

- Modern Instrumentation and Control Systems

- "Smart" Instrumentation

Basic Principles

Data Communications Standards

- RS-232 interface standard

- Faultfinding

- RS-422 interface standard

- RS-485 interface standard

- Interface Converters

DAY 2

ISO OSI Model

Communications Media

- Cabling

- Shielding

- Grounding

- Fibre optics

Error Detection

- Checksum

- Cyclic Redundancy

LAN Standards

- Topologies

- Protocols

- CSMA / CD (Ethernet)

- Token Ring

- Token Bus

DAY 3

Modbus

- Fundamentals

- Frame format

- Function coding

- Exception reports

- Troubleshooting

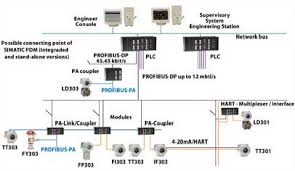

HART

- FSK

- Cabling and configuration

- Commands

Actuator Sensor Interface (ASI)

- Physical layer

- Modulation principles

- Components

DAY 4

CANBus/DeviceNet

- Frame format

- Arbitration

- Fragmentation

- Error reporting

- DeviceNet media layer

- Network configuration

Profibus

- FMS

- DP physical layer

- PA physical layer

Foundation Fieldbus

- Comparison between Profibus PA and FF

- Publisher/subscriber model

- Physical layer

- Frame structure

- Link active scheduler

- Function block

- Device descriptions

DAY 5

Ethernet

- Ethernet frame

- Media Access Control

- Collision detection

- 100Base-T repeater rules

- Gigabit Ethernet 1000Base-T

- Gigabit Ethernet MAC Layer

Internet Layer OProtocols

- Internet Protocol Version 4 (IPv4)

Host to Host (Transport) Layer Protocols

- Transmission Control Protocol

- Ports and Sockets

- Sliding windows

- Establishing a connection

- User Datagram Protocol (UDP)

- Modbus over TCP