Introduction

Oil and Gas transactions are conducted globally, each and every day. The aim is to do this as accurately as possible. Although there are different methodologies available to the user, it is a known fact that an inaccurate device (or a device that presents a measurement that is less then precise), can cost either the buyer or the seller millions of dollars, due to reading discrepancies.

As not all measuring devices meet the stringent requirements required for fiscal flow measurement, this seminar steps up to the next level, and explores each one of those devices that can meet the current high international standards. These devices are internationally recognized, and operate within the stringent norms of accuracy, repeatability and auditability.

This seminar will highlight:

- Everything that is specific and relevant to flow conditions at the point of measurement

- Fiscal measuring technologies currently utilized (from differential pressure right through to Coriolis)

- The operating principle of each technology with respect to performance, properties, uses, application, installation, calibration, advantages and disadvantages, et cetera

- How to select the best device for the task at hand

- Understand proving, calibration, maintenance, meter runs and other aspects that go together with fiscal flow measurement

Objectives

The seminar focuses on transferring knowledge that is relevant and applicable to fiscal metering systems, in a manner that is deemed to be insightful and meaningful. At all times, the abilities of the delegates are considered, and the instructor interaction and participation revolves around this.

At the end of this seminar, you will learn to:

- Develop a full understanding of accepted equipment and technology currently being used

- Analyze each unique situation, and suggest a working solution that complies with legislation and standards

- Implement a complete fiscal flow metering system, from conceptual stage to commissioning

- Apply methods applicable to calibration and auditing, which comply with international best practice

- Design a fully functional fiscal flow metering system, that complies with the company requirements of each delegate

Training Methodology

Several training techniques are utilized. Theoretical components are presented in small chunks, which allows for the maximum transfer and retention of information. The use of video material is included, to reinforce theoretical understanding. Practical exercises form the basis of the seminar, and these are either done in an individual or a group environment, depending on how the greatest effect may be achieved. The seminar starts and ends off with a pre-and post-course evaluation, and includes an Internet based assessment at the end of each chapter, to evaluate individual understanding.

Organizational Impact

Each delegate will leave with a thorough knowledge and understanding of the subject matter, and it goes without saying that this knowledge will benefit the organization that employs the individual. Knowledge obtained by the delegate, will have an impact, on the organization, in the following way:

- A thorough foundation in the fundamentals of fluids as well as gas laws will be conveyed

- All aspects pertaining to internationally accepted fiscal metering systems are covered

- International standards, pertinent to accepted fiscal metering systems, are discussed in full

- Not only will fiscal metering systems be discussed, but also additional aspects related to the measurement, such as chromatographs and analyzers

- Proving systems will be meticulously covered

Personal Impact

On a personal level, candidates will find the following of great value:

- They will gain specialized skills and knowledge in the field of fiscal metering

- They will develop greater confidence in being able to specify the best device for a specific application

- They will improve their insight and ability allowing them to discuss all aspects pertinent to fiscal flow measurement

- They will become a well-respected member in discussions and decisions revolving around fiscal measurement

- They will improve their own comfort levels, when discussing the subject matter with like-minded specialists

Who Should Attend?

There are a wide variety of people that will find this workshop beneficial. Everyone involved in fiscal flow measuring systems (from management to workers) stand to gain tremendous knowledge from the material being presented.

This seminar is suitable to a wide range of professionals but will greatly benefit:

- Managers

- Engineers

- Process personnel

- Commissioning staff

- Supervisors

- Financial staff

- Auditing staff

- Maintenance staff (of all disciplines)

SEMINAR OUTLINE

DAY 1

Properties of Fluids and Applicable Gas Laws

- Principles pertinent to flow measurement

- Bernoulli’s laws and equations and formulae specific to flow

- Variations in the flow profile

- The Reynolds number

- Viscosity, and everything associated with it

- Information relevant to ideal gases

- Assorted gas laws

DAY 2

Aspects and Characteristics of Measurement and Meter Performance

- Fiscal metering systems, and characteristics associated with them

- A consideration of ranges through which the flow may progress

- Theoretical aspects pertinent to flow including (but not limited to) sensitivity, linearity, reliability, performance, stability and accuracy

- Fiscal flow measurement in the real world, looking at numerous installations

- Determining the correct size of a flow measuring system

- Calibration of fiscal flow metering systems

DAY 3

Differential Pressure, Positive Displacement and Turbine Flow Meters

- Full insight into differential pressure flow meters, with specific attention paid to orifice plates, Venturi tubes, pitot and averaging pitot tubes and flow nozzles

- The international standard (AGA 3) applicable to orifice plates

- Full insight into positive displacement flow meters, with specific attention paid to rotor, oscillating piston, oval gear and rotating paddle devices

- Slippage and volume displacement

- Full insight into turbine flow meters

- Erosion, corrosion, cavitation as well as conditions that can cause blockages and obstructions

- The international standard (AGA 7) applicable to turbine devices

DAY 4

Ultrasonic, Turbine, Electromagnetic Flow Meters and Coriolis Mass Flow Systems

- Full insight into ultrasonic flow meters

- Straight pipe run requirements

- The international standard (AGA 9) applicable to ultrasonic devices

- Full insight into magnetic flow meters

- Full insight into Coriolis flow meters

- The international standard (AGA 11) applicable to Coriolis devices

DAY 5

Measurement Systems, Sampling, Proving and Equipment that is Specific to Flow Computing

- How meter factors influence fiscal measurement

- The relationship between fiscal measurement and meter runs

- Proving systems, concentrating on direct, indirect, master meter, volume and displacement proving systems

- Chromatographs

- Sampling systems

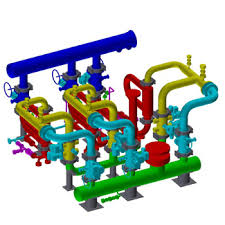

- Skids

- The influence of time delays on certain systems

Flow computers, serial data communication and other miscellaneous measurements associated with the school flow measurement