Introduction

This interactive, applications-driven 5-day training course offers a professional approach providing access to decision making support tools in asset management-operations decision making. It will show how the use of big data analytics can support strategic initiatives; to inform on asset management data information; and to direct subsea & marine operational decision making.

This course is aimed at addressing a global industry “age gap” by providing a link to a knowledge management based pool of highly experienced professionals and leaders across the Offshore & Marine- Subsea Operational and Technology sectors.

The industry is going through a period of a combination of tightening international asset maintenance standards, and the cyclic challenges presented by a global industry where oil and gas price volatility is pushing down operating entities and contractor-service providers profit margins, and having to deal with issues associated with ageing assets are forcing oil and gas operators to assess their existing strategies and develop something more robust such that one maximises the return on investment (ROI) budget levels.

Something that inevitable falls out of these periodic downturns is experienced personnel leave the industry, thus providing a significant gap in the available skills, and management leadership.

Alongside this, asset integrity has become far wider and more diverse; with modern day asset integrity managers becoming responsible for a wider remit of roles whilst still being expected to fulfill their traditional activities.

So this course will better prepare you as an aspiring subsea or marine operations engineer for both the interesting and challenging journey and career of becoming the Lead Operations owner operator engineer or possibly a Asset Manager; These roles will involve more subsea infrastructure installations by way of long subsea tie-backs to shore or subsea –marine offshore facilities involving a Floating Production Storage and Offloading (FPSO) or possibly a Floating Liquefied Natural Gas (FLNG) or Floating Re-Gasification Storage Unit (FSRU) facilities in the development and extraction of numerous stranded Oil & Gas gas fields by re-deployable mobile assets.

This training course will feature:

- Discussions on the latest subsea inspection technologies and operational maintenance recommended best practices

- The importance of using Big Data analytics to assist more predictive maintenance modelling from reliability centered maintenance tools. Introduction to condition performance monitoring (CPM) processes, providing real time asset surveillance techniques of your Marine Asset

- Focusing on asset management interpretation of statistical evidence and focused management leadership decision making

- How to integrate real time data monitoring into the day to day work domain

- Workshops presentations on practical risk management tools

- Sessions on building your Operational Knowledge and Team Leadership skill sets

- Classroom sessions on competency programs and building your knowledge retenion profile

- Providing a wide overview of how the Offshore Subsea + Marine Technology sector is evolving and still developing technology that can save on both Capital expenditure (CAPEX)+ Operating Expenditure (OPEX) costs

Objectives

By the end of this training course, participants will be able to:

- Have the tools and awareness to make quality and timely decisions

- Explain the scope and structure of what it takes to become a Operations or Asset Manager

- Apply and plan a cross-section of useful subsea inspection, periodic preventative planned maintenance routines or subsea intervention operations

- Interpret meaningfully and critically assess statistical or predictive asset database evidence

- Improve your knowledge and understanding across subsea + marine Life of Field operations management recommended best practices, regulatory reporting regimes

- How to prepare and develop operations and asset management budgets, develop mandatory safety case regime reports

Intended Skill Outcomes

- IDENTIFY how to improve the operability and integrity of subsea developments- marine assets over the life of field operations

- LEARN how to improve reliability in subsea + marine projects/ assets

- APPRECIATE the challenges of and solutions for future subsea + marine operations

- GET BETTER UNDERSTANDING of key design, installation and operation issues through a number of case studies

- UNDERSTAND the system maintenance, safeguarding measure and environmental compliance and concerns, regulatory regimes, safety case responsibilities

- GAIN INSIGHT INTO the latest edition of API RP 17N and DNVGL-RP-0002 and how to apply these within the management the uncertainty of reliability/ availability and improve asset integrity, operability throughout the life of field operations

- INCREASE KNOWLEDGE ON key operability issues of subsea systems and marine infrastructures via the use of condition performance monitoring technologies and predictable modeling tools in order to increase the maintenance free operating periods of the asset

- RECOGNIZE the requirements, the components and functions of subsea systems and marine assets as a subject matter expert

- FIND OUT how to use reliability techniques to proactively manage failure risk and integrity throughout the asset life cycle

- DISCOVER new subsea and marine technologies and best practices from experienced industry professionals

- REVIEW a combined condition performance monitoring and predictive methodology tools and practices for improved subsea –marine asset operational integrity management

Training Methodology

This training course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented:

- PowerPoint presentations, operational video’s, training manuals with practical user examples. Competency assurance tests, continuous professional development measures

The daily workshops will be highly interactive and participative. This involves regular discussion of applications as well as hands-on exposure to techniques using examples from the offshore work place environment. Delegates are strongly encouraged to bring and share their own experiences, lessons learnt from the work domain. This adds greater relevancy to the content. Emphasis is also placed on building industry knowledge sharing and skills transfer to the next generation.

Who Should Attend?

This training course is suitable to a wide range of professionals but will greatly benefit:

- New Graduates and Professionals in both operations and onshore to offshore asset management support roles with 3 to 4 years and 10+ years of experience respectively

- Reliability or Operations+ Maintenance Engineers, Field Supervisors who typically encounter operational support data / analytical information regularly in their work environment

- Those who seek to derive greater decision making value and develop their experience and subsea + marine operations knowledge

SEMINAR OUTLINE

DAY 1

Setting the Scene in Operational and Life Cycle Asset Management

- Introduction: The Life of a subsea or marine operations engineer, supervisor or Asset Manager

- Thinking clearly about dealing with statistical data, managing risks, applications in management of and developing your knowledge, industry awareness, (identifying and developing Key Performance Indicators (KPIs)

- Managing teams of multi-disciplined personnel

- Managing various Data Sets: Handing and retaining the important raw material of data analytics (types, quality and data preparation) across safety performance, inspections, maintenance and repair programs. Improved use of business enterprise management systems.

- Developing your personal technical and soft skill sets in people management, clear communication at all levels, as an aspiring leader or existing manager. Together with putting procedures and processes in place for next generation skill s transfer and competency developments across a International business sector to enable people and teams to perform and operate to consistent standards that are measurable, and auditable by any independent person or authority level to your organisation or independent regulatory body such as HSES or Upper Management teams.

DAY 2

Subsea Operations from Commissioning a Subsea well System to Developing Operational Subsea Inspection and Maintenance Budgets for Offshore Assets

- Learn how to develop appropriate Key Performance Indicators (KPIs) in relation to safety performance and the production assurance uptime performance of your subsea-marine operating asset, which are aligned to specific, measurable, achievable, realistic and time-bound (SMART) objectives

- Building Team Leadership Communication, presentation skills, + reporting tools.

- Introductory Overview from the start up and commissioning a subsea well system from a FPSO or FLNG facility to the planning of period subsea inspection/maintenance and repairs (IMR) and the data documentation asset integrity management data base repositories and how all of these aspects are managed by an owner operating entity

- Work Shop Session on subsea simulator facility which is one of many tools capable of supporting the owner operator manage the asset throughout its operating life cycle

- Completing a subsea well and handing it over to the owner operator process along with an understanding of how to maintain certification documentation and recorded inspection reports using latest software technologies

Typical Subsea XT –Production Flow Module Interfaces

- Intelligent Wells with Subsea Data Communication Hubs and Programmed Autonomous Underwater Vehicle (AUV) uploads various data to vessel over life of field support operations

DAY 3

Subsea Architecture and Topside Surface

Interfaces Onboard FPSO or FLNG Facility (* variable dependent up the asset) with a big emphasis of safety, operability and integrity over the life of field operations:

- Topside Hydraulic Power Unit (HPU) design with detailed considerations for planned preventative maintenance and periodic repairs and the topsides interfaces of the Master Control Station (MCS) and how this links to latest condition performance monitoring technologies.

- Riser/ controls umbilical-pull-in Interfaces configurations includes onshore umbilical pull-ins

- Control philosophy- Design and Reliability / Operability aspects

- Electro-hydraulic & multiplexed E-H---Thermo plastic hose type umbilical’s versus steel tube design life criteria issues over 25 years to 30 years + life of field operations

- Open Loop (Water Based Fluids) Vs. Closed hydraulic systems (Mineral Oil based) and impact on integrity over life of field

- Flow control, operability response to well systems (Examples) will be discussed and reviewed with API- RP-17N and DNV–RP -00002 criteria in mind.

- Fluid Flow monitoring, fluid cleanliness standards being maintained and periodically checked

- System design with Condition Performance Monitoring (CPM)

- Designing for high reliability / availability with considerations on subsea interventions (Maintenance & Repair) accessibility operability over life of field operations

- Case Study Application exercises - North

- Sea Sector UKCS– West of Shetland Long Offset Subsea Tie-back to shore

- 140km SPCS Functional Design; development requirement, the

- Participants will be guided to design (30 year field life) and focus on reliability/ availability compliance

- This will cover the main considerations of control requirements and condition performance monitoring (CPM) latest state of the art industry technologies, power and communications, steel tubes umbilical design to shore side plant and on the production risers and interfaces with FPSO or FLNG vessel in remote and hostile sea state conditions, challenging operational environment

- Overview of Failure Mode Effects Criticality Analysis (FMECA) to Reliability, Availability, Maintainability (RAM) analysis requirements will be explained and discussed in detail by worked examples-exercises. Most importantly the learning outcome will be what these studies mean to the subsea operations engineer/ asset owner operator

DAY 4

Operability, Planning Period Subsea, Marine Facility Inspections, Maintenance and Repair Asset Integrity

- Maintaining a stable Integrity Performance for your assets – Managing the Risks over Life of Field

- Focusing on asset-specific troubleshooting on deepwater Diver less Intervention repairs and subsea controls maintenance / intervention

- Examples will be tabled: on Subsea XT’s, manifolds, template/manifolds and Pipeline or Flowline End Termination manifolds [PLEM- FLET] Subsea structures — controls and subsea isolation interfaces

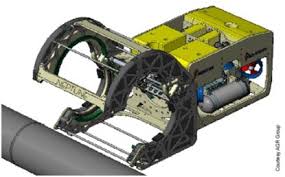

- Various Remote Operated Vehicles [ROV—ROT Remote Operational Tooling] intervention presentations on different subsea designs and comparisons of different functional specifications used in selected International Far East assets

- Workshop examples will be discussed: New Concepts to Secure Access to Any Type of subsea Reservoir with a Mobile Redeloyable Floating Production Facility

ROV Operated Inspection Tools

- UKCS -Norwegian sector assets and with examples from West Africa to deepwater Brazil operational environments. Such that issues encountered from design, operability and subsea maintenance or difficult repair aspects are reviewed in an Independent and professional manner across the respective sessions

- Using data stream analysis for maintenance and fault diagnosis or real time troubleshooting

- Reliable future subsea system solutions and equipment

- Method of minimizing intervention costs and delivering a guaranteed up-time asset performance

- Examples of production assurance program system design to operational phase model that is practical for operations technician’s personnel to understand

- Failure, repair and availability optimization

- Component failure-rate modeling

- Failure mode analysis

- Redundancy & common-mode failures+ lessons learnt

- Typical redundancy option

- Technical Risk Categorization following API-RP-17N guidelines

- Reliability Assurance Documentation (RAD) Requirements during Feed

- Reliability Assurance analysis

- Detailed Reliability Process training – workshop discussions, activity descriptions

- Reliability Value Analysis (CAPEX, OPEX) and evaluations worked examples from recent projects

- Procedures for defining availability goals and requirements in projects

- Risk and Availability Analysis following the DNVGL-RP-0002 recommended guidelines

- Worked FMECA and Fault Tree Analysis examples Technical Risk Categorization guidelines

- Reliability Assurance Documentation (RAD) Requirements during Feed and streamlined for operational retention purposes as per DNVGL latest recommended guidelines

- Reliability Assurance analysis and understanding of the various techniques

- Detailed Reliability Process training – workshop discussions, activity description

- Application Example from a deep-water design review exercise subsea integrated drilling / production template manifolds versus satellite cluster well configurations: with simulator modeled output

- Alarm and shutdown philosophy

- Fail-safe approaches, safety integrity level (SIL) criteria

- Implementation of IEC61508 on subsea production control systems

- Integrated Control & Safety Systems

An insight to latest technologies in Emergency Pipeline Repair Strategies, tooling and equipment requirements both Diver Assisted and Deepwater diver less technologies

DAY 5

Offshore Operations Onboard a FPSO and or FLNG Production Asset and How to Practice your Operational Leadership Skills

- The influence of the ship’s hull motion affecting structural interfaces and equipment integrity from topside and the interfaces with risers and controls umbilical’s to the subsea infrastructure

- Safety in operations and maintenance

- Introduction to FPSO –FLNG Operation and Maintenance again very much an end to end understanding of the system and its life cycle

- Operation Requirements from a subsea well system, subsea flowlines, pipelines, subsea manifolds, riser bases, etc.

- Inspection -Maintenance – Guidance and General Requirements

- Plant Inspection

- Overview of FPSO –FLNG Process Systems+ Safety Critical Elements( SCE)- Operational Performance Standards(PS)

- Understanding how to put in place a Asset Life Extension Plan -Program

- Environmental influences affecting FPSO –FLNG Operations

- FPSO and or FLNG Mooring, Turret and Swivel operations

- Subsea Umbilicals, Risers + Flowlines (SURF) and Subsea facility Interfaces

- Phased Installations, Pre-Commissioning to Commissioning and Operational Readiness Practices

- Oil or Gas Transfer (Offloading) - Examples in both FPSO + LNG Carrier Tandem Mooring to FLNG assets, using cryogenic hoses

- Day to Day Safety in Operation and Maintenance responsibilities, real time data reporting and onshore to offshore access to information updates

- Understanding of the Marine Warranty Surveillance and Owner-Operator Asset Insurance Requirements

- Summary of key learning and how these fit into your continuous professional development training and competence measurement profile, leadership + management skills retention