Introduction

Petroleum Refining-Production Planning, Scheduling and Yield Optimization is combination of two modules specifically designed to run consecutively. Attendees are given a detailed overview of all major refining processes and are familiarized to the most commonly encountered production planning and scheduling issues in petroleum refineries, how to identify them and resolve them.

Additionally, the training course will present a detailed outline of refining process yields optimization, from the crude oil feed to the finished products. Issues of operations scheduling for petroleum refining are discussed in depth and enhanced with planning and scheduling and yield optimization examples.

This training course is oriented toward the practical aspects of refinery operations as well as the terminology and economics of refining.

The seminar is split into two modules:

MODULE I - Production Planning & Scheduling in Petroleum Refineries

MODULE II - Refinery Process Yield Optimisation

Each module is structured and can be taken as a stand-alone course; however, delegates will maximise their benefits by taking Module 1 and 2 back-to-back as a two-week seminar.

Objectives

The key objectives of this comprehensive training course are as follows:

- Gain an appreciation of production planning and scheduling tools that will be useful for planning of crude and product deliveries

- Differentiate and appreciate the similarities and differences between planning and scheduling

- Understand the principles of scheduling optimization and promote efficient refining operations, and yield optimization

- Learn the skills to crude selection and optimization that result in improved profitability

- Develop the skills necessary to apply blending techniques using excel

- To familiarize and understand the various refinery types and appreciate how refining complexity impacts refining optimization and refining margins

- Comprehend the importance quality giveaways and learn how use practical excel spreadsheets for blending calculations to reduce quality giveaways

- Use hands on software that allows professionals in the industry to choose different crude diets to optimize refinery utilization efficiency and profitability

- Act as a primer into the industry of Petroleum Refining and familiarize industry professionals with all processes associated with the processing of petroleum into finished products

- Equip new engineers into the industry, with the basic tools for understanding the complex nature of Refining and its operations

Training Methodology

Petroleum Refining-Production Planning, Scheduling and Yield Optimization is a hands-on, stimulating learning experience. The training course will be highly interactive, with opportunities to advance your opinions and ideas. Participation is encouraged in a supportive environment.

To ensure the concepts introduced during the course are understood, they will be reinforced through a mix of learning methods, including lecture style presentations, open discussions, case studies, and short videos. Hands on computer software and simulations will be provided to illustrate the application of planning and scheduling. The case studies provided for group work will be re-enforced with practical exercises and ample opportunities for deliberation and sharing of experiences.

Attendees will have the opportunity to develop personal competencies and build up expert knowledge of crude oil production planning, scheduling and yield optimization in a range of equipment.

Who Should Attend?

This course is intended for:

- Refining professionals working in the industry either as refining technologists or in refining operations and engineers

- All professionals involved in Production, Planning and Scheduling

- Process engineers and technologists engaged in planning and scheduling activities and who are required to understand and discuss issues related to their industry

- Operations personnel including shift supervisors

- Marketers and refinery planners

- Blending professionals

- Refining Technologists

- Other engineers who would like a further understanding of the complex refining processes

- Accountants, marketers and other professions who would like understand the complexities and terminology of Production Planning & Scheduling in Petroleum Refineries

- Anyone who wishes to update themselves on the methods used in this important field and learn how to implement error free methods for the benefit of their organizations

SEMINAR OUTLINE

Module I - Production Planning & Scheduling in Petroleum Refineries

DAY 1

Application of Planning and Scheduling

- Overview of planning and scheduling in oil refineries

- Refinery Complexity

- Refinery Configuration

- Integrated Refineries

- Choice of Crude

- Crude oil scheduling

- Capacity utilization of Crudes & Operational Efficiency

- Workshop - Cut-point Optimization

DAY 2

Improving Product Movements and Releasing Tankages

- Crude Assay

- Intermediate Feed Characteristics

- Yields and Properties

- Different Process Units

- Storage Tanks

- Custody Transfer/Measurements

- Class Exercises: Using Excel - Yield Optimization

DAY 3

Product Blending Rules

- Product Specifications

- New Trends in fuel production

- Environmental Issues

- Crude oil pricing regimes

- Product Netback

- Class Workshop: Blending exercises

DAY 4

Refinery Flow Sheets

- Refinery Flow-sheets

- Simplified Material Balance

- Product Inventory Control

- Product Quality Control

- Fixed Composition Blend

- Capacity Control/ Constraints

- Availability of Feedstock/ Control

- Case study: Gasoline Blending and Its Impact on Operations

DAY 5

Refinery Planning and Scheduling

- Petroleum Product Movement and Product Exchange

- Marginal Depot Supply and movements

- Crude Selection Strategies

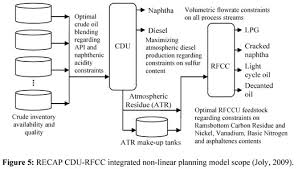

- Linear Programming and Fundamentals of Supply Chain Management for Refining

- Refinery Planning and Scheduling

- Discussion and Summary

Module II - Refinery Process Yield Optimisation

DAY 6

Crude Oil Yields Refinery Technology

- Introduction to Crude Oil Origins & Characteristics

- Crude oil Assay and properties

- Crude oil products & Product specifications

- LPG

- Gasoline

- Kerosene/ Jet Fuel

- AGO / Diesel Fuel Oil

- Petrochemical Feedstocks

- Overall refinery flow: Interrelationship of processes

DAY 7

Petroleum Refinery Processes

- Crude Processing

- Desalting

- Atmospheric distillation

- Vacuum distillation

- Heavy Oils Processing / Bottom of the barrel upgrading

- Cocking and Thermal Processes

- Delayed Coking

- Fluid Coking

- Flexicoking

- Visbreaking

- Case study – example

DAY 8

Process for Motor Fuel Production

- Fluid catalytic cracking

- Hydrocracking

- Cat Cracking

- Isomerization

- Alkylation

- Hydrotreating

- Catalytic Reforming

- Case study – example

DAY 9

Supporting Operations

- Blending for Product Specifications

- Hydrogen production

- Refinery Gas Plants

- Acid Gas Treating

- Sulfur Recovery Plants

- Utilities

- Case study – example

DAY 10

Refinery Economics

- Residue Reduction

- Asphalt and Residual Fuel

- Refinery Complexity and Netback

- Economic Evaluation

- Cost Estimation

- Case Studies

- Group Discussions

- Program Evaluation & Summary