Design, Commissioning, Operation, Maintenance,

Introduction

The successful operation of any Generating Systems ultimately depends on how well the inspection, testing, maintenance and troubleshooting functions are carried out. Well-developed procedures and planning will in the long run result in reduced costs, equipment down time, parts requirements and troubleshooting complexity.

The Generator Excitation systems seminar has been developed to not only allow delegates to learn new skills associated with Generator systems, but it has also been developed to allow delegates to refresh their previous skills and training, to allow further advancement of knowledge.

This seminar will highlight:

- Power Generator systems

- Test equipment and testing techniques

- Information required to understand Generator system operation

- Fault finding techniques and inspection

- Standards associated with Generator systems

- Replacement of components

- Safe working practices

- Synchronisation issues

Delegates are encouraged to participate by active involvement in group discussions, practical exercises and sharing experiences.

Objectives

At the end of this seminar, you will learn to:

- Elaborate on different types of power systems

- Discuss different types of technical information

- Examine different types of test equipment used with power systems

- Explore different types of switch gear associated with Generator systems

- Identify Excitation techniques for Generators

- Describe trouble shooting techniques used with Generator and Excitation systems

Training Methodology

Each seminar participant will receive a copy of the comprehensive seminar notes. The presenter will outline and discuss the topics using computer displays, CD displays and videotapes. The seminar is designed to have an interactive format to maximize delegate participation. Questions and answers are encouraged throughout and at the daily sessions.

Case studies and examples will be discussed in problem solving workshop sessions. This gives participants the opportunity to discuss with other delegates and the presenter their specific problems and appropriate solutions. Only minimum note taking is encouraged to ensure maximum delegate attention during the seminar.

Organizational Impact

The seminar will allow delegates to learn new skills to improve efficiency and technical competence of Engineering teams. It will also allow delegates to do the following;

- Current practices onsite can be reviewed (and changed) to bring the workplace up to current standards.

- Engineers and Technicians can gain knowledge to apply in their individual work roles so that they can understand current procedures and practices, should their work role not be a fully ‘hands-on’ role.

- Updating of technical skills and Standards from previous learning.

- Technicians, Engineers and Managers will be able to apply current work practices, for compliance with legislation.

- All candidates will be made aware of upcoming changes to practices and legislation, so that they can be pro-active in their work roles and implement the changes quickly and efficiently.

- Candidates can progress onto further Power related seminars, which Glomacs can provide.

Personal Impact

On successful completion of this seminar, delegates will be able to:

- Develop a structured approach to the operation, inspection, testing and troubleshooting of electrical generating equipment plus provide solutions for various electrical generator problems

- Maintain a continuing understanding of test equipment used for electrical inspection and servicing

- Better understand the design, functionality and failure modes of electrical generating equipment and their control systems

- Provide examples of successful operating, inspecting and troubleshooting techniques and hands-on experience plus case studies and group problem solving exercises

- Utilize single-line diagrams and schematics for troubleshooting

- Better understand standard work practices plus develop job plans, which assist in successful inspection and troubleshooting

- Refresh the delegate’s knowledge of electrical safety

Who Should Attend?

This seminar is suitable to a wide range of professionals but will greatly benefit:

- Electrical Engineers

- Electrical Supervisors

- Electrical Technicians

SEMINAR OUTLINE

DAY 1

Definitions, Interpretation and Use of Drawings, Maintenance Planning and The Use of Test Equipment

- Generator systems (AC) and equipment

- Generator systems (DC) and equipment

- Operation, inspection, testing, control, maintenance and troubleshooting

- Control systems

- Single-line electrical drawings

- Control schematics, Wiring lists

- P&ID’s

- Logic and standard symbols

- Developing schedules and procedures

- Define operation requirements for parts and labor

- Define maintenance requirements for parts and labor

- Regular, preventative, predictive and emergency maintenance

- Digital voltmeter (DVM)

- Oscilloscopes

- Megger

- Frequency meter

- Temperature probes/pyrometers

- Ammeters

- Power meters

- Load banks

- Digital hydrometers

- Cable fault locators

DAY 2

The Technology of Generators

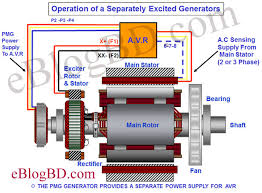

- Principles of electrical generation (AC, DC and Emergency)

- Power supplies (battery chargers, rectifiers, inverters)

- Batteries

- Generator Drivers (gas/steam/water turbine, diesel/gas engine)

- Governors (control systems)

- Programmable logic controllers (PLC)

- Synchronization

- Power grid and network considerations

DAY 3

The Technology of Generators and Inspection and Testing of Generators

- Increasing or decreasing the voltage (transformers)

- Neutral ground resistors (NGR)

- Switchgear

- Motor control centers (MCC)

- Disconnect switches

- Power monitoring

- Control relays/timers/switches

- Generator protective devices

- Methods

- Terminology

- Principles

- Special techniques

- NEC check lists

DAY 4

Troubleshooting of Generators, Development of a Job Plan and Review of Safety Requirements

- Methods

- Terminology

- Principles

- Special techniques

- Case studies/examples

- Single line drawings

- Group exercises

- Identification of the troubleshooting step-by-step sequence

- Procedure preparation

- Documentation

- Follow-up

- Safety considerations and training

- Area classifications

- NEC electrical codes

- Safety information

DAY 5

The Identification and Repair of Problems/Failures

- Common mode failures

- Phase imbalance

- Contact pitting/arcing

- Electronic component failure

- Fusing

- Generator windings/bearings/brushes

- Excitation circuits

- Battery cells

- Inverters/rectifiers/battery chargers

- Bushings

- Switches

- Control circuits

- Ground faults