Course Overview

If Maintenance planning is the aim to have a world-class enterprise, the maintenance organization and strategy have a critical role to play in this mission. Driven from business goals, such a strategy cannot be seen as separate from other functions, but rather as an intrinsic part of a complete approach to high performance operation.

The business goals will place organizational, as well technical demands on the enterprise. The strategy therefore has to integrate and guide the implementation of technical and managerial strategies at all organizational and process levels.

The strategy/philosophy must represent the very best technology, procedures and practices available, relevant to the business goals of the organization.

Course Objective

This five days training course will provide participants with a through background in the concepts of Planning and Scheduling Engineering.

The course addresses how to identify, monitor, and balance information crucial for the successful management of projects.

It will discuss the development of a baseline performance management plan (PMP) for the project that will allow the efficient compilation and the timely generation of quantitative performance comparisons.

The comparisons highlight significant performance departures ("actual vs. baseline") and allow for preventive and early remedial and corrective actions.

• The Practical sessions will provide hands-on experience.

Who Should Attend?

- Engineering Managers

- Continuous Improvement Leaders

- Maintenance Engineers

- Operations Managers

- Maintenance Managers

- Reliability Engineers

- Project Managers

- Engineers and Planners, Technicians

Course Outline

DAY (01):

- Introduction

- The Development of Maintenance Systems

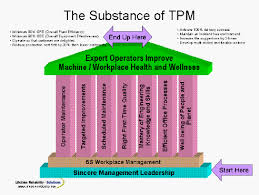

- The Pillars of TPM

- The Pillars of RCM

- TPM—Basic, Use, and Ideal Conditions

- Fault Development

- The Basic Condition

- Technical Standards

- Overall Equipment Efficiency

- The availability of the equipment

- The performance of the equipment

Day (02):

- TPM—Analyzing and Categorizing the Failure Data

- TPM: The Education & Training and Safety Pillars

- The TPM Education & Training Pillar

- Equipment training

- A sequence for training equipment

- Competency: How does TPM assess the skill level of the team members?

- The TPM Safety Pillar

- The area map

- The hazard map

- Risk assessment

- Safe working procedures: Using as standards

Day (03):

- RCM—Reliability Centered Maintenance

- Equipment Defined as Functions

- Identifying Functions and Labeling

- Functional Failures to Failure Effects

- Failure modes

- Failure effects

- Time-and Condition-Based Maintenance

- Introduction to On-Condition Maintenance

- Friction between Maintenance and Production

Day (04):

- SMED—Single Minute Exchange of Die

- Where Did SMED Originate?

- Step 1: Creating the SMED Team

- Applying SMED to Maintenance and the Use of Turnaround Parts

DAY (05):

- Deciding on a Maintenance Strategy

- TPM PM Analysis

- The malfunction and PM maps

- Interpreting PM maps

- Scheduled maintenance or scheduled restoration

- Scheduled replacement or scheduled discard

- The RCM PM Analysis

- The RCM decision diagram

- Failure is unacceptable: Redesign the system

- Recording the process on the decision worksheet

- Failure finding and calculating acceptable risk

09. Fault Analysis: A Few Ways to Help Find Root Causes

- Fishbone Diagrams

- Fault Tree Diagrams

Training Methodology

- Presentation & Slides

- Audio Visual Aids

- Interactive Discussion

- Participatory Exercise

- Action Learning

- Class Activities

- Case Studies

- Workshops

- Simulation